Boiler burners play a crucial role in the efficient combustion of fuel within industrial and residential boilers, providing the necessary heat to produce steam or hot water. Selecting the right type of burner for a specific application can significantly impact energy efficiency, emissions, and overall performance. In this article, we'll explore the various types of boiler burners and discuss their advantages in terms of efficiency, emissions, and adaptability.

Types of Boiler Burners

1.Gas Burners: These burners utilize natural gas or propane as their primary fuel source. They are popular for their clean combustion and relatively low emissions. Gas burners are widely used in residential heating systems, small-scale industrial boilers, and commercial applications.

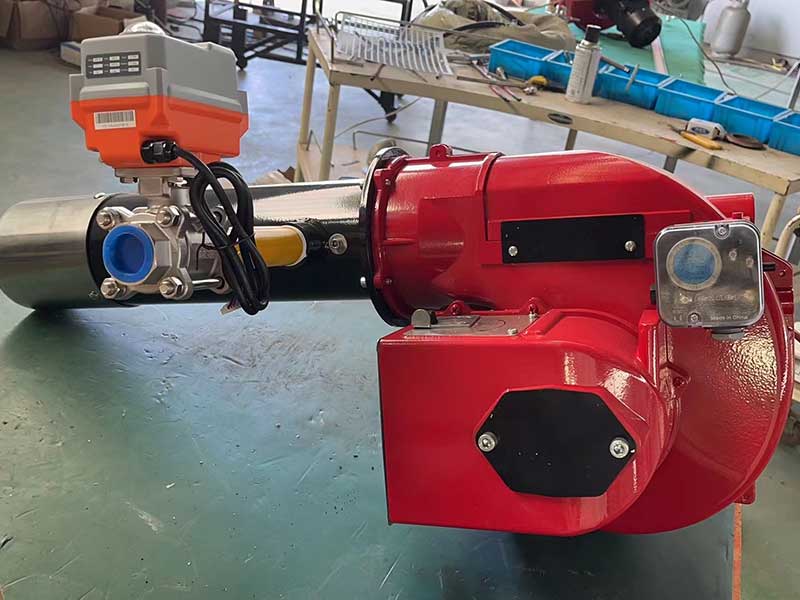

2.Oil Burners: Oil burners are designed to burn various types of liquid fuels, such as diesel, heavy oil, and biodiesel. They are commonly found in industries where gas infrastructure is limited or unavailable. However, oil burners typically produce more emissions and require more maintenance than gas burners.

3.Dual-Fuel Burners: These burners are capable of using both gas and oil as fuel sources. They provide flexibility by allowing operators to switch between fuels based on availability, price, or emission regulations. Dual-fuel burners are often used in situations where fuel supply stability is a concern.

4.Solid Fuel Burners: Solid fuel burners are designed to burn materials like coal, wood pellets, or biomass. They are commonly used in biomass boilers, which offer a more sustainable approach to energy production by utilizing organic materials. Solid fuel burners can contribute to reducing carbon emissions and promoting the use of renewable resources.

5.Combustion Air Systems: While not a separate type of burner, combustion air systems are essential components that influence burner efficiency. Forced-draft and induced-draft systems supply the necessary oxygen for combustion, aiding in efficient fuel burning and minimizing waste.

Advantages of Different Burner Types

1.Gas Burners:.

·High Efficiency: Gas burners are known for their efficient combustion, resulting in less wasted fuel and reduced operating costs.

·Low Emissions: Compared to oil burners, gas burners generally produce lower levels of harmful emissions, such as sulfur dioxide and particulate matter.

·Quick Ignition: Gas burners offer rapid and consistent ignition, making them suitable for applications where immediate heat is required.

2.Oil Burners:.

·Energy Density: Oil has a higher energy density than gas, which means that a smaller volume of fuel can produce a significant amount of heat.

·Fuel Availability: In regions with limited natural gas infrastructure, oil burners can provide a viable alternative for heating and industrial processes.

·Fuel Storage: Oil can be stored more easily than gas, making it suitable for situations where fuel storage is a consideration..

3.Dual-Fuel Burners:.

·Fuel Flexibility: Dual-fuel burners offer the ability to switch between gas and oil, allowing users to optimize fuel usage based on availability and pricing.

·Redundancy: In critical applications, dual-fuel systems provide a backup fuel source, ensuring uninterrupted operation in case of fuel supply disruptions..

4.Solid Fuel Burners:.

·Renewable Energy: Utilizing solid fuels like biomass or wood pellets promotes the use of renewable resources and reduces reliance on fossil fuels.

·Carbon Neutral: When managed sustainably, biomass burning can be nearly carbon-neutral, helping to mitigate greenhouse gas emissions.

·Waste Utilization: Solid fuel burners can burn certain types of waste biomass, contributing to waste reduction and energy recovery..

5.Combustion Air Systems:.

·Optimized Combustion: Properly designed combustion air systems enhance burner efficiency by providing the correct air-to-fuel ratio for complete combustion.

·Emission Reduction: Efficient combustion reduces the formation of pollutants, leading to lower emissions and better compliance with environmental regulations.

In conclusion, the choice of boiler burner type should be based on the specific requirements of the application, fuel availability, emission regulations, and sustainability goals. Gas burners are prized for their efficiency and low emissions, while oil burners provide a reliable option in regions with limited gas infrastructure. Dual-fuel burners offer flexibility and redundancy, while solid fuel burners contribute to renewable energy usage. Additionally, combustion air systems play a vital role in achieving optimal combustion efficiency and reducing emissions. Careful consideration of these factors will lead to a well-informed decision that maximizes performance and minimizes environmental impact.