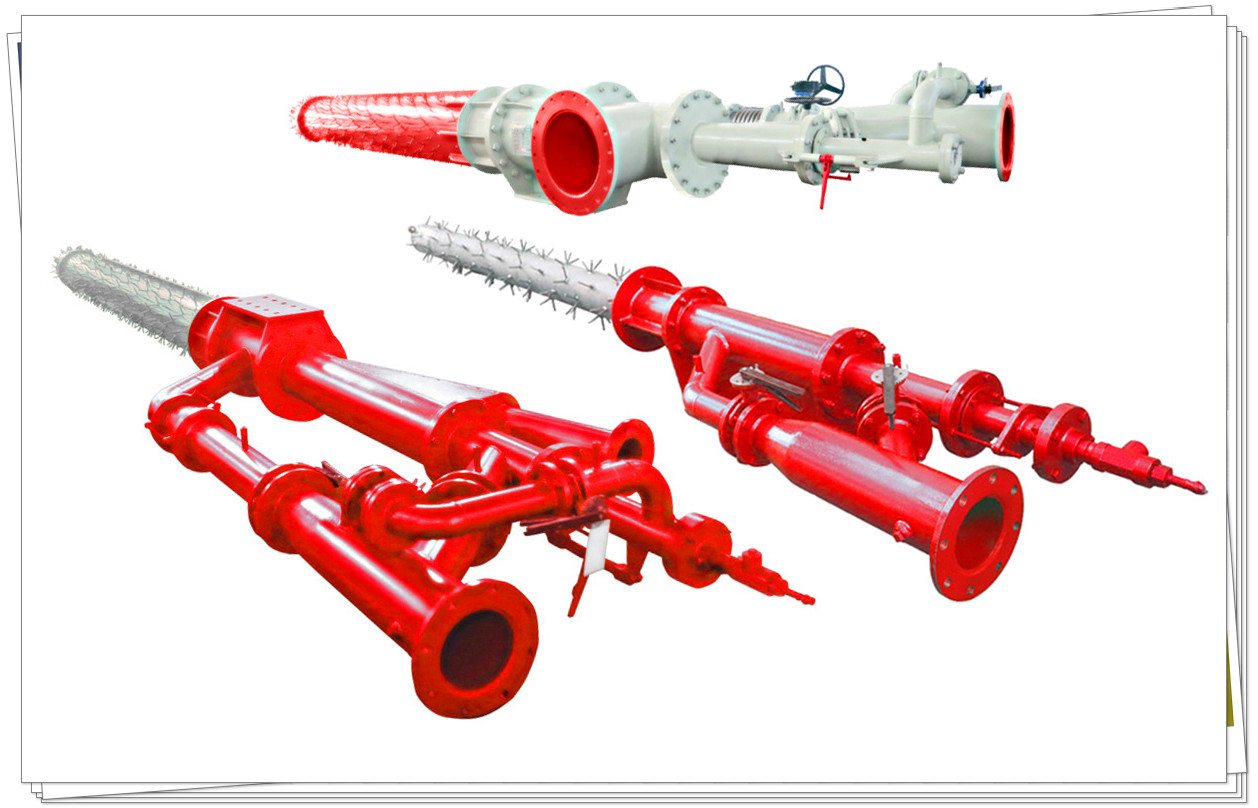

The function and operation method of the pulverized coal burner of the dryer

The pulverized coal burner is one of the necessary weapons and equipment to determine whether the lignite dryer can produce high-quality flames. When equipped, pay attention to the ability to adjust the flame, and change the position, length and length of the flame according to the height and condition of the raw material composition. In this way, the system tail temperature and head temperature can be controlled. If the head temperature is not high, it can indicate the maintenance level of the head. If the tail temperature is too high, it indicates that the material is not sufficiently ignited. Evenly symmetrical and stable coal quality), when the coal quality changes, the mixing range of gas and raw coal can be changed according to the adjustment of the inlet and outlet wind power, so that the flame can still be considered for calcining, and environmental protection regulations must also be considered.

1. Technical statistics of pulverized coal burners

1. The blackness of the smoke and dust discharged from the pulverized coal burner is Ringelmann 0-1;

2. The desulfurized gypsum in the pulverized coal burner has a fixed carbon water content of 0.1% or less, and the foundation has no carbon powder;

3. The environmental protection and energy saving rate of the new pulverized coal burner is 15-30%;

4. The moisture content of the smoke and dust in the combustor is changed to the lower exhaust flue under the condition that the exhaust flue does not have a dust removal device. If the wind coal is sufficiently ignited, it can exceed the national industry standard.