Project Overview

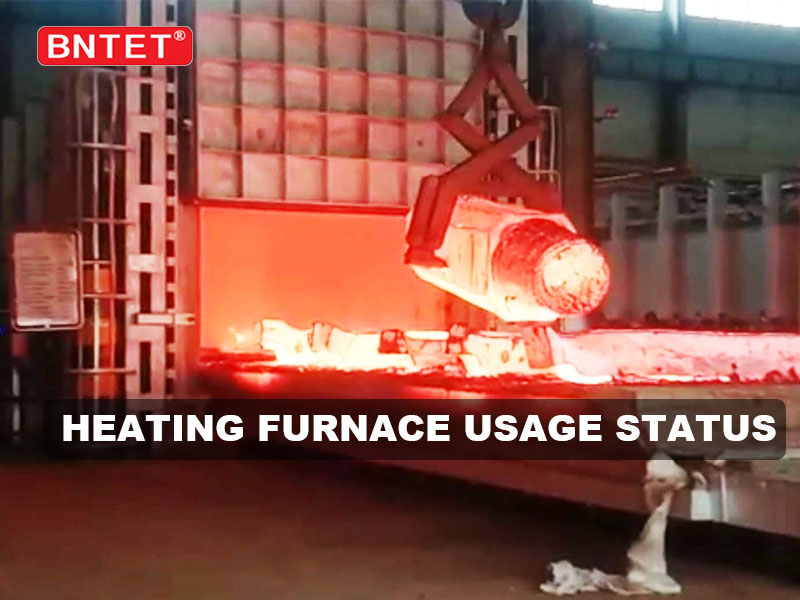

We completed a gas burner system upgrade for a large steel enterprise in Pakistan, successfully addressing key challenges in energy consumption, temperature control, and environmental compliance.

Customer Pain Points

Excessive energy consumption, leading to high production costs

Unstable heating temperatures, affecting product quality

Failure to meet local environmental emission standards

Frequent equipment maintenance, disrupting production continuity

Solution

We provided a customized gas burner system, including:

High-performance gas burner assemblies

Intelligent combustion control system

Gas pressure stabilization unit

Exhaust gas treatment module

Implementation Results

Significant reduction in energy consumption, lowering production costs

Greatly improved temperature control precision

Full compliance with emission standards

Noticeable enhancement in equipment operational stability

Customer Feedback

The customer expressed satisfaction with the upgrade results, particularly praising our expertise in addressing gas pressure fluctuations and the technical proficiency demonstrated throughout the project execution.

Project Significance

This project not only improved the customer's production efficiency and product quality but also provided strong support for their green manufacturing goals, establishing it as a benchmark for industrial energy efficiency upgrades in the region.

For more details or inquiries about similar solutions, please feel free to contact us.