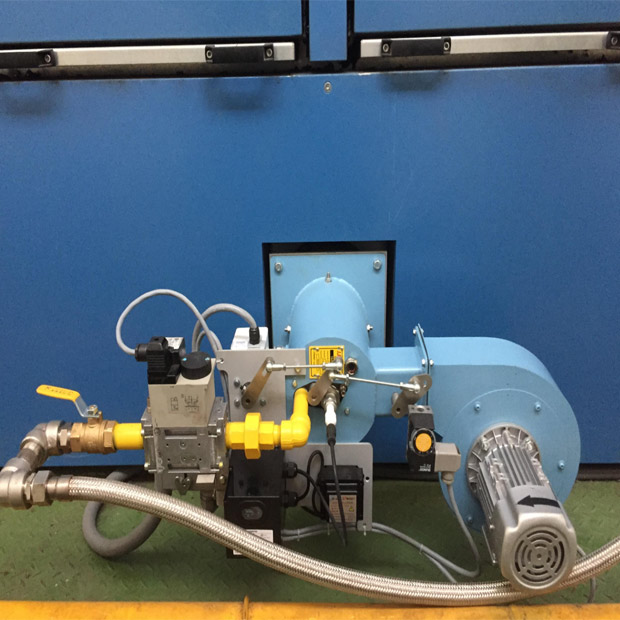

Low temperature burner of stenter setting machine for coating machine

Low-temperature burners are used in coating machines, stenter setting machines, textile equipment and other different machinery, and are usually called stenter setting machine burners, natural gas low-temperature burners, etc. The working principle of the burner of the automatic coating machine The working principle of the automatic coating machine is the same, but its performance varies according to different models and different manufacturers. The low-temperature burner screen coating machine is equipped with a device that can clamp the screen frame on the vertical frame. Before and after the screen area is a horizontal coating mechanism, which consists of a coating tank, and mechanical or pneumatic components that control the angle and pressure of the coating tank.

The two ends of the coating mechanism are installed on the vertical support arm of the coating machine, and the coating mechanism moves up and down through the transmission of belt, chain or cable, and coats along the surface of the screen. The transmission mechanism is connected to the servo or frequency conversion motor, so that the operation is stable, and the position of the coating mechanism can be accurately controlled.

The drying oven manufactured by the manufacturer of the burner of the stenter setting machine. Its drying effect should be no problem. Because the socks produced now are relatively thick. Therefore, it has an impact on the drying effect. In order to make the drying effect better, the quality of steam must be higher. The natural gas low-temperature burner must first have enough steam to ensure the first drying, and the first drying is good. The damage directly affects the second drying effect. The quality of the first drying is determined by the amount of steam. Therefore, it is necessary to not only have pressure for steam, but also have sufficient steam flow. Secondly, the less moisture in the steam, the better.